Discover our full process, how we transform a simple micro-alga into the most powerful antioxydant in the world.

1. Microalgae cultivation

The production of astaxanthin at axabio begins with the cultivation of the microalgae Haematococcus pluvialis, nature's most abundant source of this potent antioxidant.

It is grown in our proprietary state-of-the-art photobioreactors in a controlled environment using optimized conditions for growth ensuring a reliable and sustainable supply of microalgae.

The design of our photobioreactors allows for scalable production while eliminating almost any contamination risk, essential for meeting the demands of our clients in the cosmetic and nutraceutical industries.

2. Induction phase

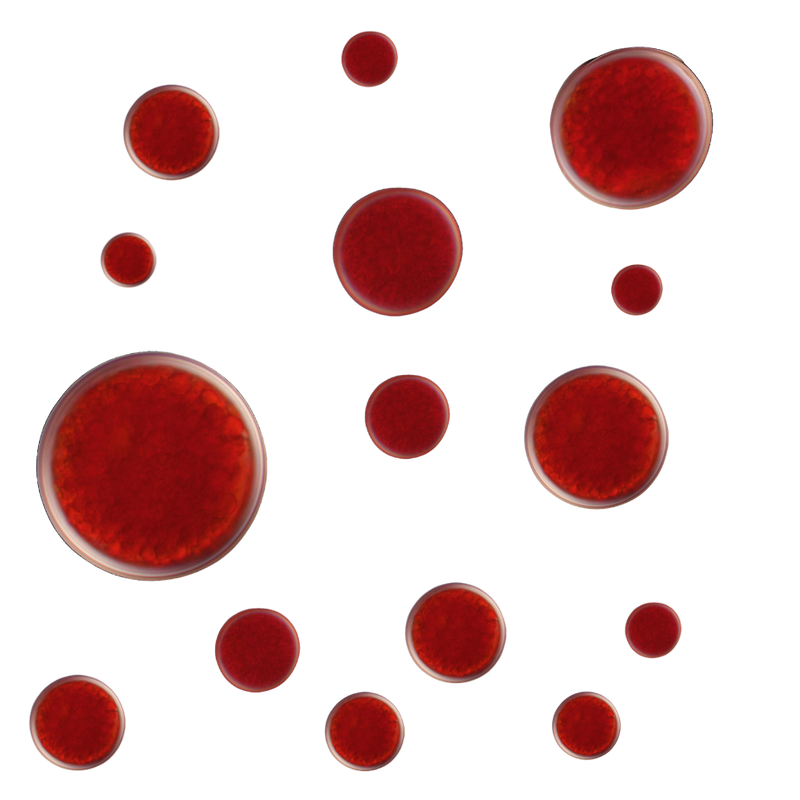

Once the microalgae have reached a sufficient density, they are subjected to the astaxanthin induction phase.

During this phase, we introduce specific conditions to the microalgae developed in house that trigger the microalgae to produce and accumulate astaxanthin as a defense mechanism.

Our own innovative approach ensures that the microalgae produce the highest levels of astaxanthin, making the process efficient and effective.

3. Harvesting process

As soon as the microalgae have accumulated the desired levels of astaxanthin, they are harvested. Advanced filtration and centrifugation techniques are employed to efficiently separate the microalgae biomass from the growth medium.

The harvested biomass is pure and ready for the next stage of processing. Proper operation of the separation process is critical to maintaining the integrity and quality of the astaxanthin.

4. Extraction process

Astaxanthin is extracted from the harvested algae by means of supercritical CO2 extraction, a green extraction method chosen for its ability to isolate astaxanthin with high purity without the use of harmful solvents.

Supercritical CO2 extraction uses carbon dioxide under high pressure at moderate temperature to dissolve the astaxanthin from the microalgae biomass.

This process ensures that the resulting extract is free from contaminants and retains the maximum potency of astaxanthin. The use of this method aligns with our dedication to ecological standards, as it is environmentally friendly and produces minimal waste.

Oleoresin production

The resulting extract is processed into an oleoresin, a concentrated form of astaxanthin. This oleoresin is highly potent and versatile, making it suitable for a wide range of nutraceutical applications.

The oleoresin can be easily incorporated into different product formulations, providing flexibility for product development. Its high concentration of astaxanthin ensures that even small amounts deliver significant health benefits.

Microencapsulation for CWD Beadlets

For our cold-water dispersible (CWD) beadlets, the extracted astaxanthin oleoresin is microencapsulated. This process involves encasing the astaxanthin in a protective coating, creating beadlets that are readily dispersible in water.

Microencapsulation enhances the stability and bioavailability of astaxanthin, ensuring that it remains effective when incorporated into various formulations. These beadlets are ideal for use in dietary supplements and cosmetic products, as they provide a consistent and reliable release of astaxanthin.

Quality Assurance, quality Control and packaging

Production is performed under the most stringently controlled and certified conditions.Our production facilities only work with the cleanest of ingredients.

We do not source from natural surface waters or other potential heavy metal, pesticide or pathogen reservoirs.

Growth media are prepared from food grade nutrients only, without the addition of any artificial preservatives. Both nutrients and supplied air are sterilized prior to application.

As a result our products contain no heavy metals and pesticides, and are free of pathogens or any other undesired biological contaminants. Rigorous quality control measures are implemented at every stage of production to ensure the highest standards of purity and potency.

Each batch of natural astaxanthin undergoes thorough testing to verify its quality and consistency. These tests include checking for contaminants, verifying the concentration of astaxanthin, and ensuring that the product meets all regulatory standards. Once the product passes quality control, it is carefully packaged to preserve its integrity and prepared for distribution.

Our commitment to quality control ensures that our clients receive reliable and effective astaxanthin products. By adhering meticulously to these processes, axabio ensures that our astaxanthin products meet the highest quality standards.

We provide our clients with natural, stable, and effective astaxanthin, backed by our values of innovation, creativity, and impact-driven approaches. This comprehensive approach not only enhances the quality of our products but also ensures that we meet the specific needs and expectations of your consumers.